Most consumers can be dismayed with how little we learn about the vast majority of chemicals. Only 3 percent of commercial chemicals – mostly drugs and pesticides – are comprehensively tested. Most of the 80,000 to 140,000 chemicals in consumer products haven’t been tested in any respect or simply examined superficially to see what harm they could do locally, at the positioning of contact and at extremely high doses.

I’m a physician and former head of the European Center for the Validation of Alternative Methods of the European Commission (2002-2008), and I’m dedicated to finding faster, cheaper and more accurate methods of testing the protection of chemicals. To that end, I now lead a brand new program at Johns Hopkins University to revamp the protection sciences.

As a part of this effort, we’ve now developed a pc approach to testing chemicals that might save greater than a US$1 billion annually and greater than 2 million animals. Especially in times where the government is rolling back regulations on the chemical industry, recent methods to discover dangerous substances are critical for human and environmental health.

How the pc took over from the lab rat

Our computerized testing is feasible due to Europe’s REACH (Registration, Evaluation, Authorizations and Restriction of Chemicals) laws: It was the primary worldwide regulation to systematical log existing industrial chemicals. Over a period of 1 decade from 2008 to 2018, at the very least those chemicals produced or marketed at greater than 1 ton per 12 months in Europe needed to be registered with increasing safety test information depending on the amount sold.

By Garsya/shutterstock.com

Our team published a critical evaluation of European testing demands in 2009 that concluded the demands of the laws could only be met by adopting recent methods of chemical evaluation. Europe doesn’t track recent chemicals below an annual market or production volume of 1 ton. But the same size U.S. chemical industry brings about 1,000 chemicals at this tonnage range to the market every year. However, Europe does a a lot better job in requesting safety data. This also highlights what number of recent substances needs to be assessed yearly even once they are produced in small quantities below 1 ton, which usually are not regulated in Europe. Inexpensive and fast computer methods lend themselves to this purpose.

Our group took advantage of the incontrovertible fact that REACH made its safety data on registered chemicals publicly available. In 2016, we reformatted the REACH data, making it machine-readable and creating the biggest toxicological database ever. It logged 10,000 chemicals and connected them to the 800,000 associated studies.

This laid the muse for testing whether animals tests – considered the gold standard for safety testing – were reproducible. Some chemicals were tested surprisingly often in the identical animal test. For example, two chemicals were tested greater than 90 times in rabbit eyes; 69 chemicals were tested greater than 45 times. This enormous waste of animals, nevertheless, enabled us to review whether these animal tests yielded consistent results.

Our evaluation showed that these tests, which devour greater than 2 million animals per 12 months worldwide, are simply not very reliable – when tested in animals a chemical known to be toxic is just proven so in about 70 percent of repeated animal tests. These were animal tests done in response to OECD test guidelines under Good Laboratory Practice – which is to say, one of the best you may get. This clearly shows that the standard of those tests is overrated and agencies must try alternative strategies to evaluate the toxicity of assorted compounds.

Big data more reliable than animal testing

Following the vision of Toxicology for the twenty first Century, a movement led by U.S. agencies to revamp safety testing, necessary work was carried out by my Ph.D. student Tom Luechtefeld on the Johns Hopkins Center for Alternatives to Animal Testing. Teaming up with Underwriters Laboratories, we’ve now leveraged an expanded database and machine learning to predict toxic properties. As we report within the journal Toxicological Sciences, we developed a novel algorithm and database for analyzing chemicals and determining their toxicity – what we call read-across structure activity relationship, RASAR.

Thomas Hartung, CC BY-SA

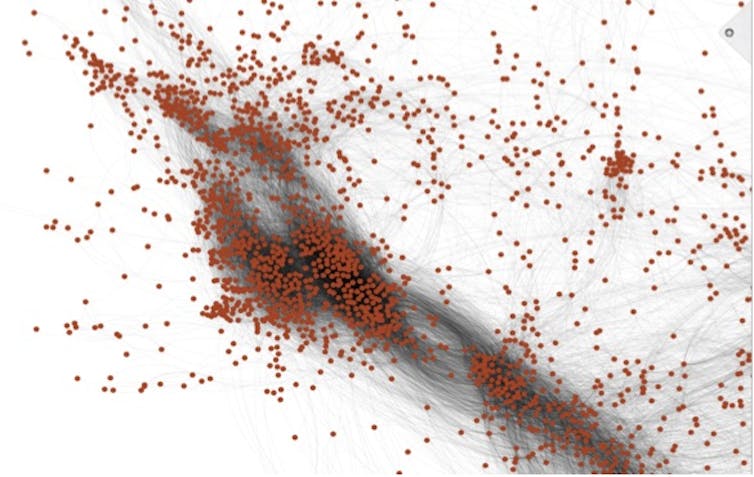

To do that, we first created an unlimited database with 10 million chemical structures by adding more public databases stuffed with chemical data, which, for those who crunch the numbers, represent 50 trillion pairs of chemicals. A supercomputer then created a map of the chemical universe, during which chemicals are positioned close together in the event that they share many structures in common and much where they don’t. Most of the time, any molecule near a toxic molecule can be dangerous. Even more likely if many toxic substances are close, harmless substances are far. Any substance can now be analyzed by placing it into this map.

If this sounds easy, it’s not. It requires half a billion mathematical calculations per chemical to see where it suits. The chemical neighborhood focuses on 74 characteristics that are used to predict the properties of a substance. Using the properties of the neighboring chemicals, we will predict whether an untested chemical is hazardous. For example, for predicting whether a chemical will cause eye irritation, our computer program not only uses information from similar chemicals, which were tested on rabbit eyes, but in addition information for skin irritation. This is because what typically irritates the skin also harms the attention.

How well does the pc discover toxic chemicals?

This method shall be used for brand spanking new untested substances. However, for those who do that for chemicals for which you truly have data, and compare prediction with reality, you may test how well this prediction works. We did this for 48,000 chemicals that were well characterised for at the very least one aspect of toxicity, and we found the toxic substances in 89 percent of cases.

This is clearly more accurate that the corresponding animal tests which only yield the right answer 70 percent of the time. The RASAR shall now be formally validated by an interagency committee of 16 U.S. agencies, including the EPA and FDA, that may challenge our computer program with chemicals for which the final result is unknown. This is a prerequisite for acceptance and use in lots of countries and industries.

The potential is gigantic: The RASAR approach is in essence based on chemical data that was registered for the 2010 and 2013 REACH deadlines. If our estimates are correct and chemical producers would haven’t registered chemicals after 2013, and as an alternative used our RASAR program, we might have saved 2.8 million animals and $490 million in testing costs – and received more reliable data. We must admit that this can be a very theoretical calculation, however it shows how invaluable this approach may very well be for other regulatory programs and safety assessments.

In the longer term, a chemist could check RASAR before even synthesizing their next chemical to examine whether the brand new structure could have problems. Or a product developer can pick alternatives to toxic substances to make use of of their products. This is a strong technology, which is just starting to point out all its potential.

This article was originally published at theconversation.com